White label trading app

Design

Develop a video-based system for quality control on a production line using AI.

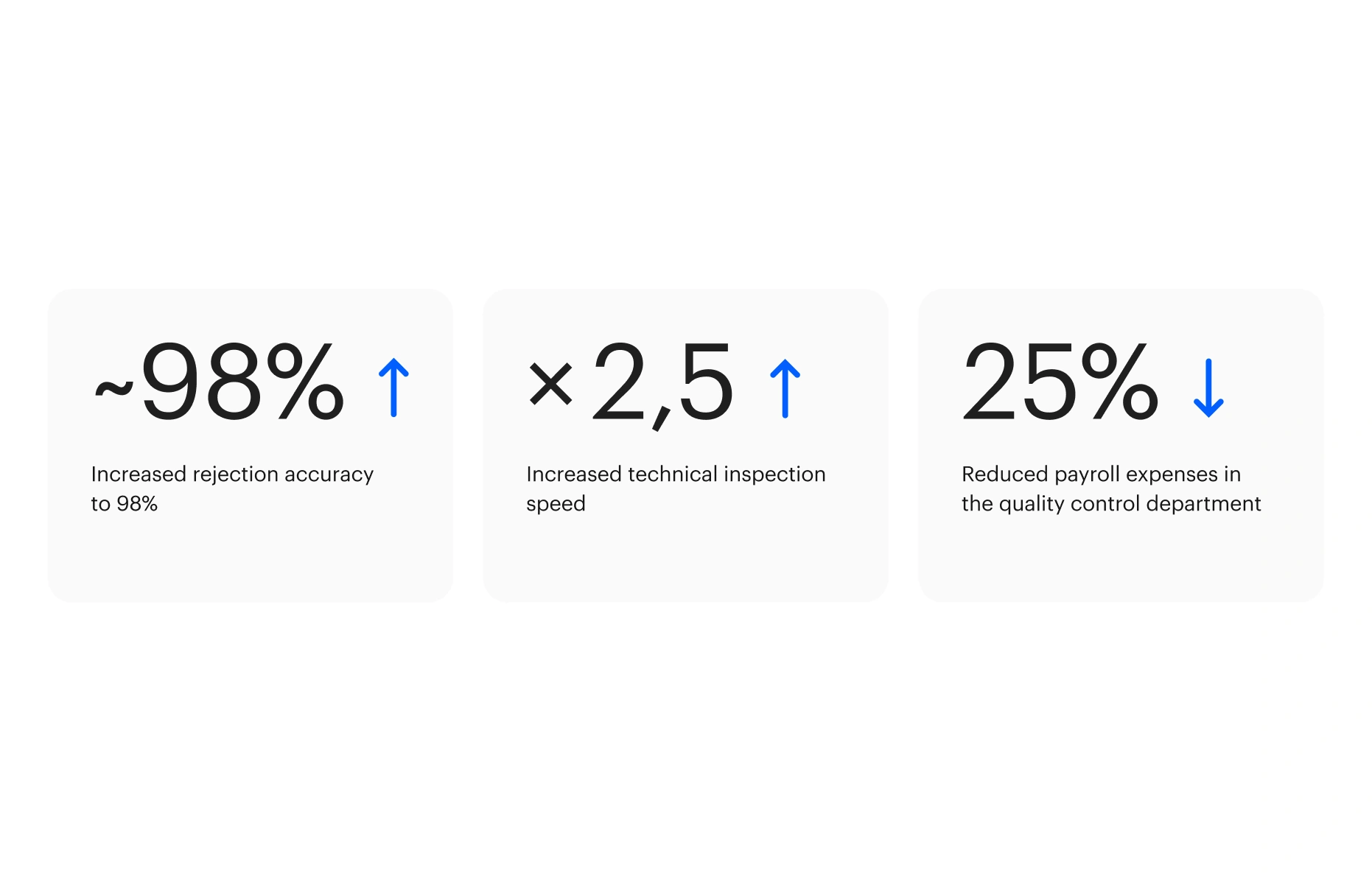

Approximately 98% defect detection accuracy, improving process stability. 2.5× faster inspections through workflow optimization and automated analysis. 25% lower payroll costs as automation reduced labor expenses while maintaining efficiency.

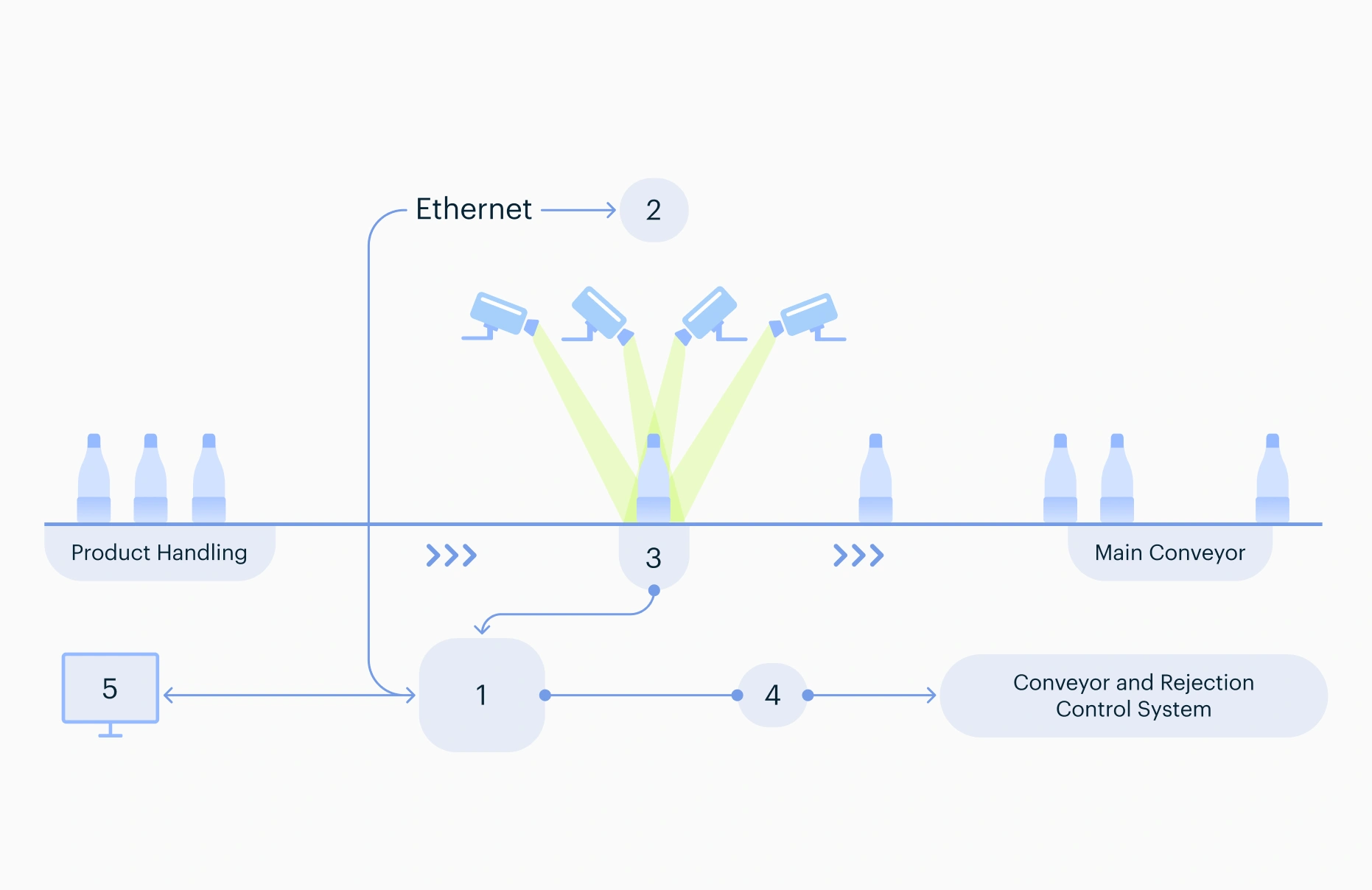

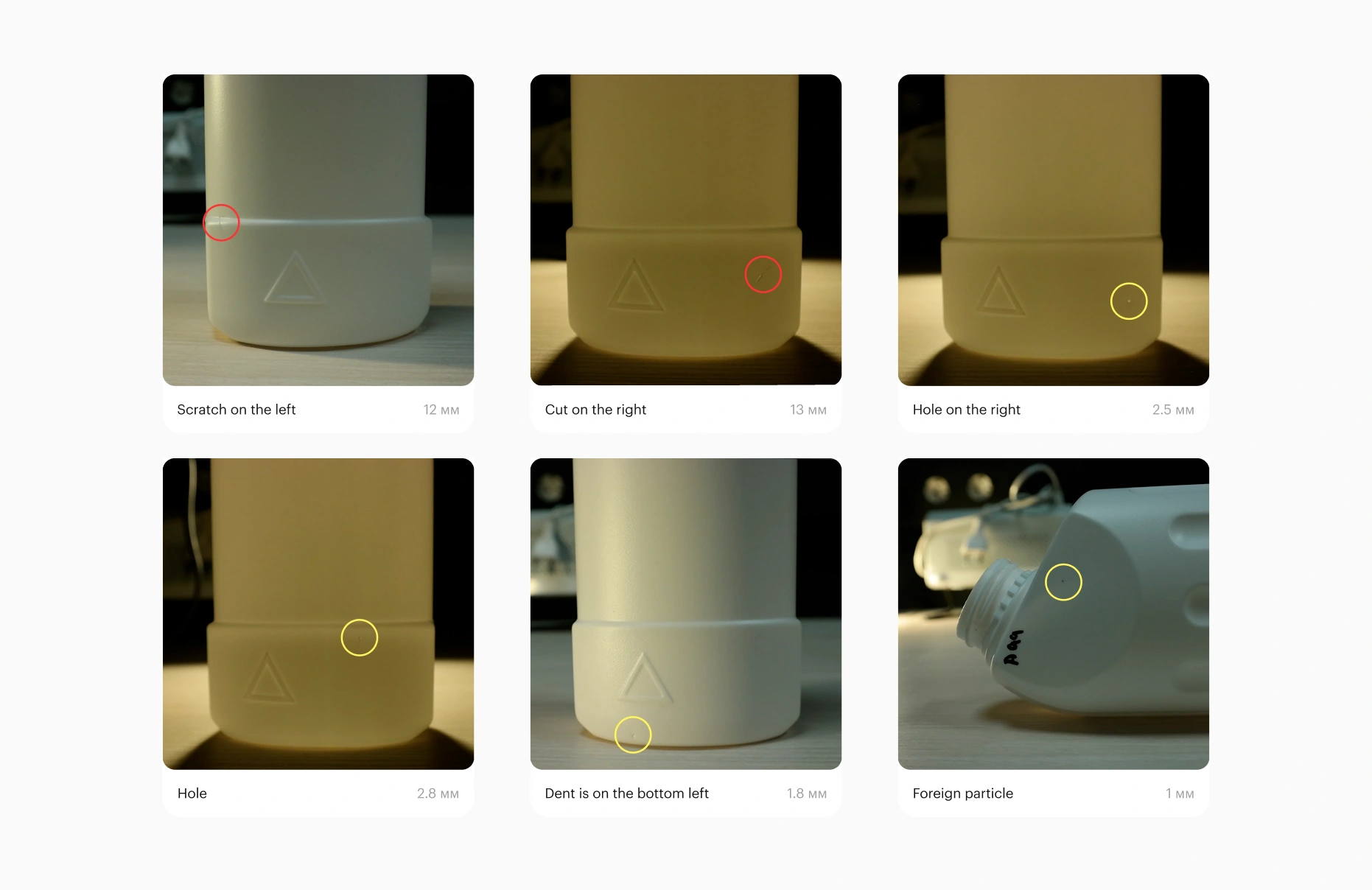

In collaboration with researchers from Saint Petersburg Electrotechnical University "LETI", we built a system that uses computer vision and machine learning to detect packaging defects.

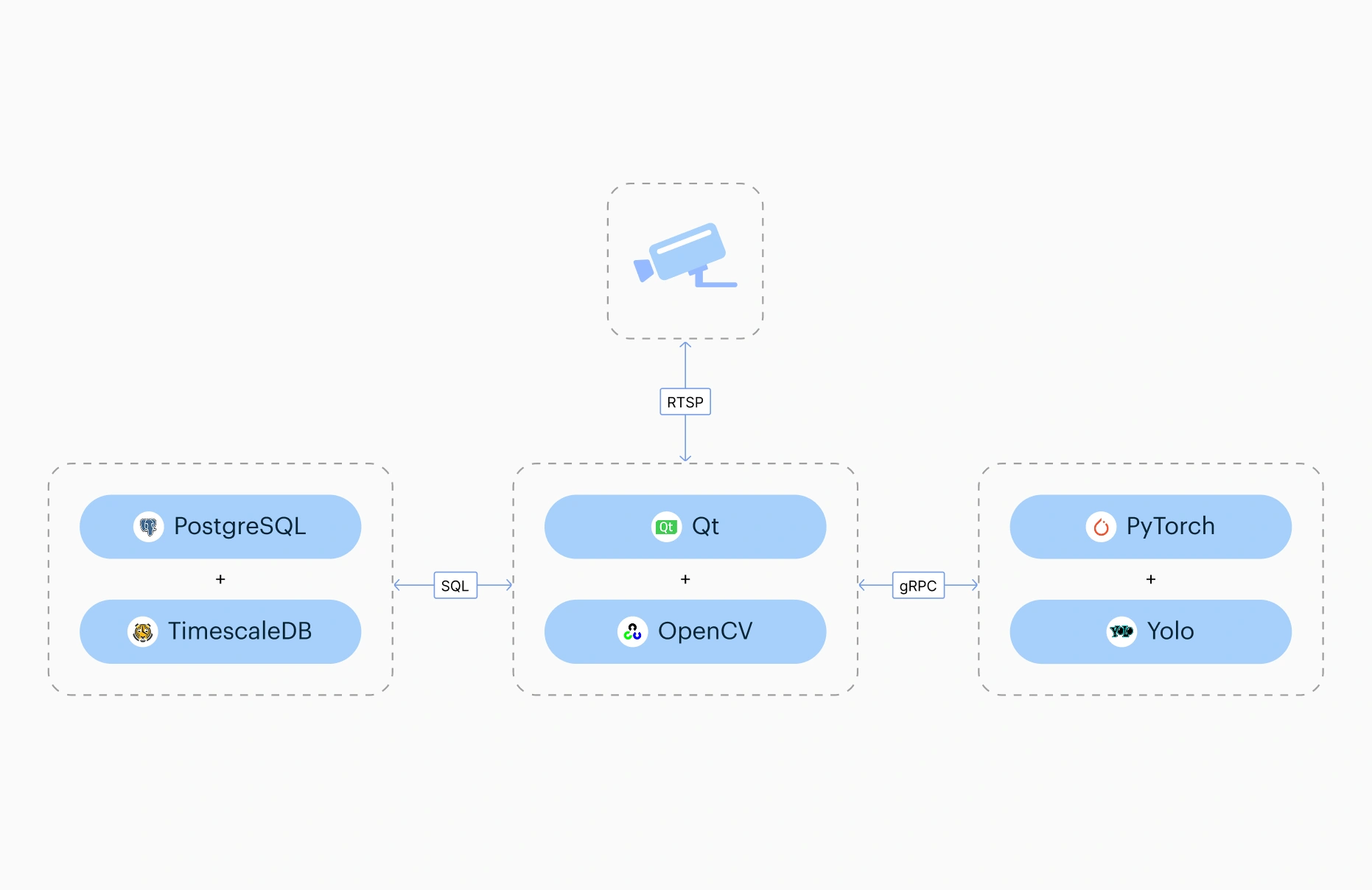

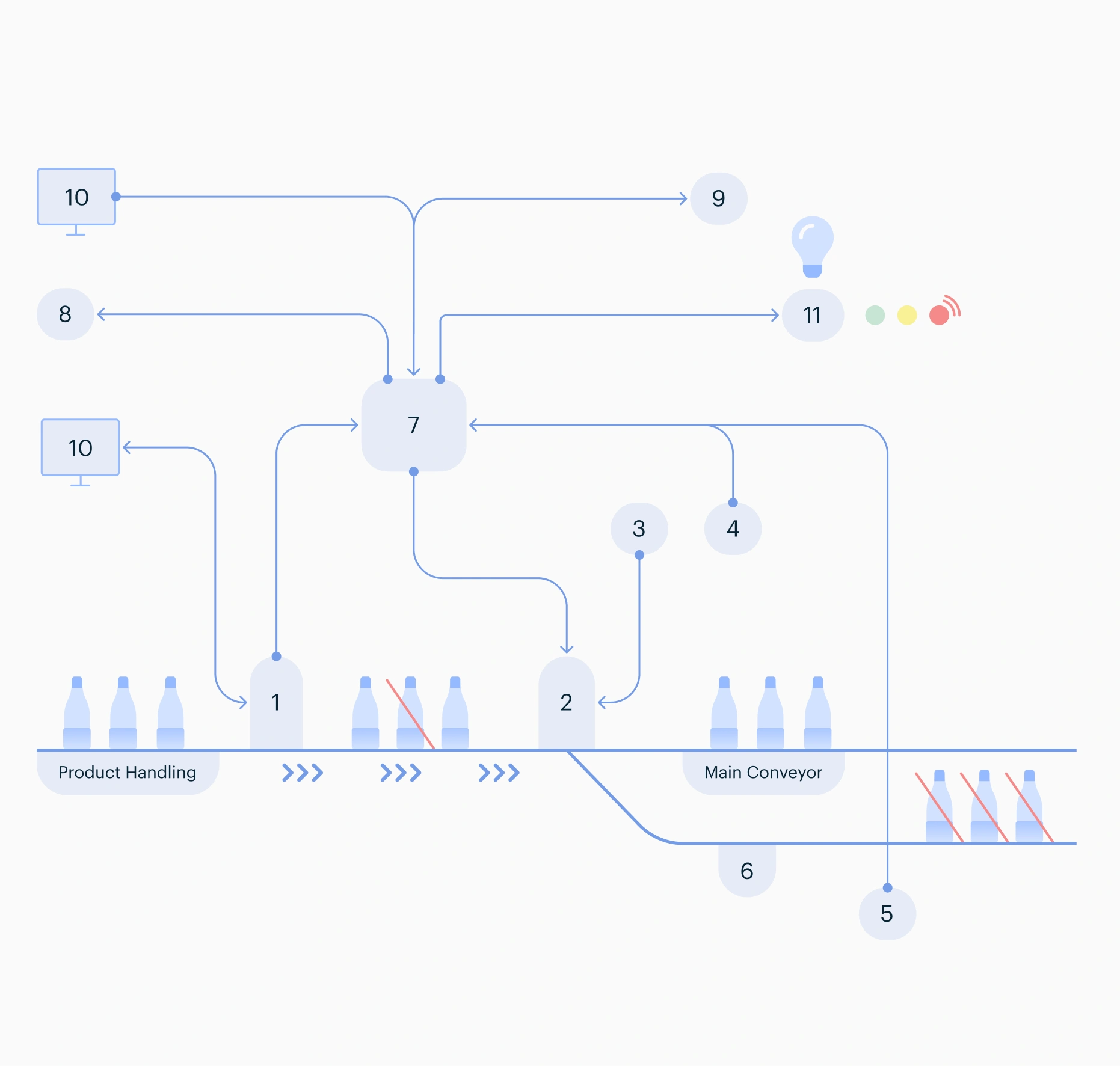

The system is based on a neural network developed in PyTorch and Ultralytics YOLO for fast and accurate object detection. The interface is implemented using Qt and JavaScript. Components are integrated via a RESTful API, while controller management is implemented in C++ using Rapid STP.

The system is deployed on the production line and ensures high defect detection accuracy.

To adapt the system to real production conditions—such as camera failures, lighting degradation, and angle variations—we conducted a series of test shoots that replicated situations on the conveyor line. By adjusting viewing angles and lighting, we fine-tuned the system and achieved the required defect‑detection accuracy without disrupting production.

Each defect is categorized by color: green—within normal limits, amber—above normal but not critical, and red—significantly above normal.